Metallurgical examinations involve the analysis and evaluation of metallic materials to determine their properties, structure, and performance. These examinations can include both macroscopic and microscopic analyses to identify surface and internal features, such as grain size, phase distribution, and defects.

Metallurgical examinations are crucial to many industries to ensure materials meet specific standards and are suitable for their intended applications.

Here are two techniques:

Stereo Microscopes Examination

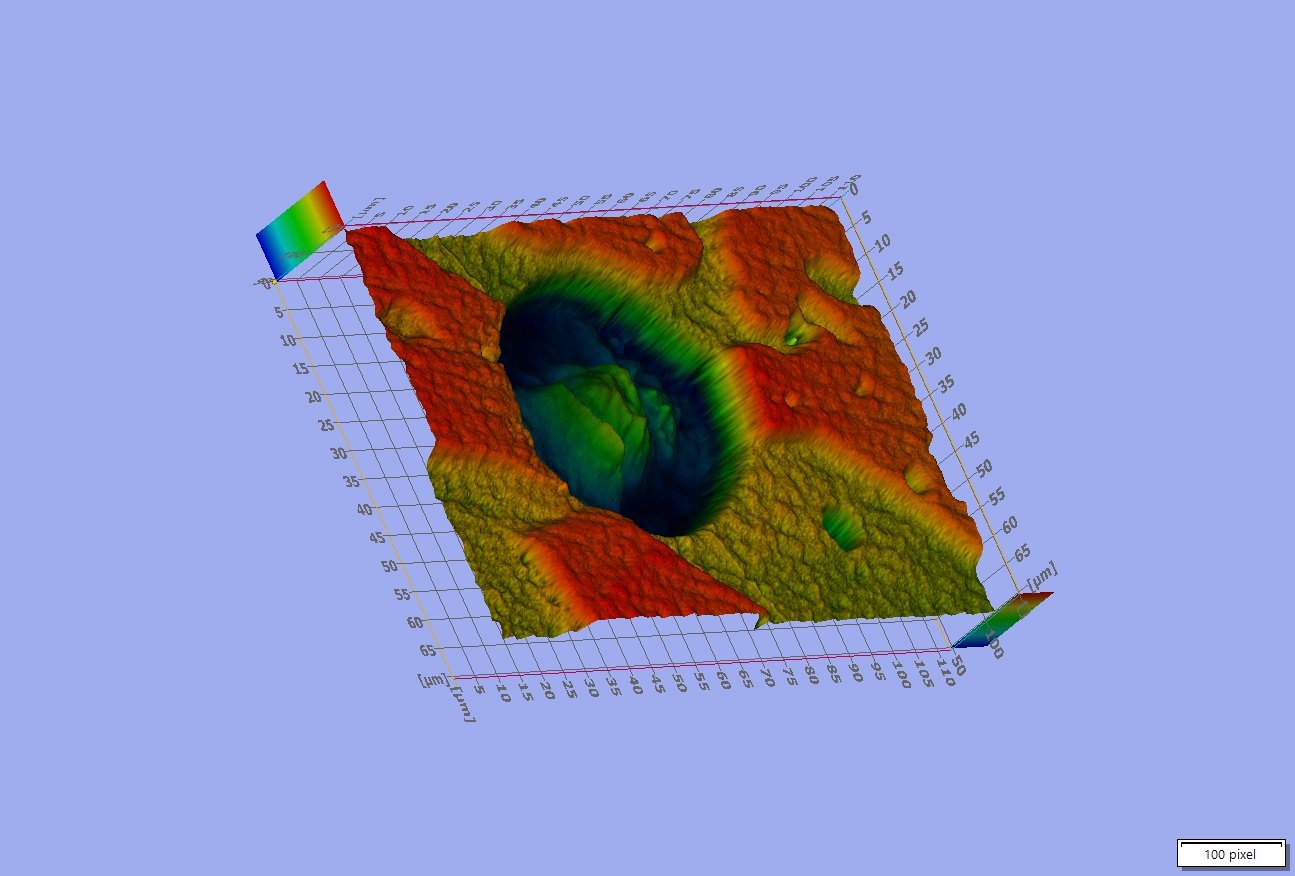

Stereo microscopes, or dissecting microscopes, are specialized tools used for examining three-dimensional objects at low magnification levels yet, allows for the detailed observation of specimens that cannot be viewed under traditional microscopes. Our equipment can reach magnification up to 500X to better examine the defected sample’s surface, assess damage features and pattern, capture fractography evidences correlated to damaged mode.

Microstructure Evaluation (Optical Microscopy)

Analyses of microstructure and material defects in cross-sectioned samples to determine material properties, flaw characteristics, and defect mechanisms. Grain size measurements of ASTM E112-13, GB/T 6394-2002, DIN 50601:1985 & EN ISO 643:2012. Phase contrast analysis to distinguish formation and precipitation of carbides and inter metallic phases.