Explore Our Services

Metallurgical Industrial Services

When a component fails unexpectedly, metallurgical examination can determine the root cause of the failure. This involves examining the microstructure, composition, and mechanical properties of the failed material to identify any defects, imperfections, or weaknesses. This can be extended to components where remaining life assessment is required to be determined to define how long that component can run safely with reliable performance.

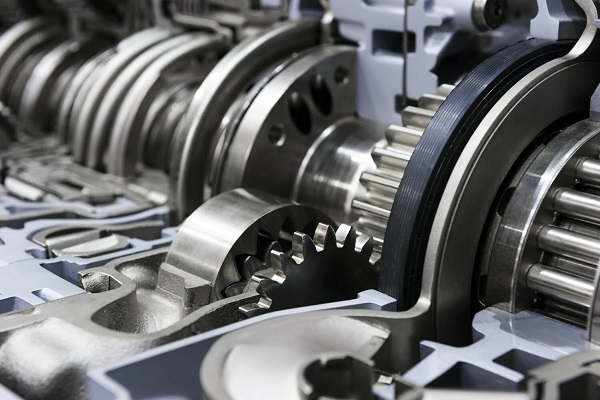

Machinery Industrial Services

Machinery Industrial Services encompass a broad spectrum of specialized support aimed at optimizing the performance, reliability, and safety of machinery within various industrial sectors. These services are integral to maintaining operational efficiency, reducing downtime, and ensuring compliance with safety and regulatory standards.

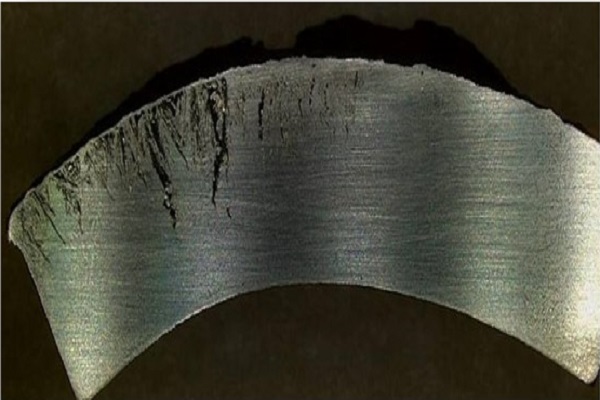

Failure Analysis Investigations (Metallic & Nonmetallic)

Failure analysis investigations are applied across many industries to prevent future asset and product failures as well as protecting against potentially dangerous risks to business, people, and the environment.

Materials Evaluation and Corrosion Studies

MASFIC can provide customers with detailed and comprehensive understanding of a simulated lifetime performance of materials, components, and systems, even for facilities and devices operating under harsh and corrosive environments.

Mechanical Testing

Mechanical testing involves evaluating the mechanical properties of materials, such as strength, toughness, and hardness, to ensure they meet specific performance standards. This testing is crucial for determining the suitability of materials for various applications, from construction to aerospace.

Chemical Analysis

Chemical analysis involves determining the physical properties or chemical composition of samples of matter. This process is essential for ensuring the quality, safety, and compliance of products across various industries. It plays a critical role in research and development, helping to innovate and improve materials and processes.

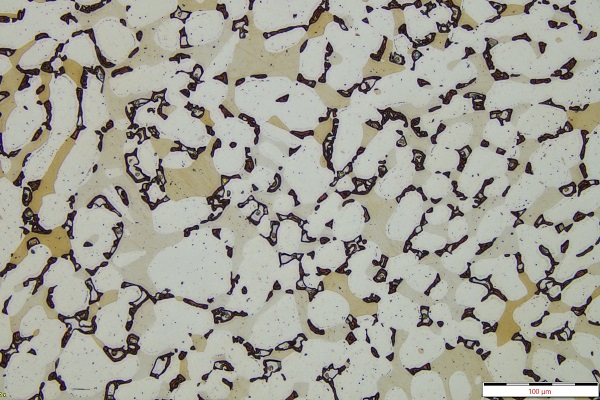

Field Metallographic Replication

Replication is used as a tool for evaluating microstructures and other surface features in lieu of laboratory evaluations through destructive examinations. This non-destructive technique allows for detailed analysis and documentation without compromising the integrity of the original sample.

Metallurgical Examinations

Metallurgical examinations involve the analysis and evaluation of metallic materials to determine their properties, structure, and performance. These examinations can include both macroscopic and microscopic analyses to identify surface and internal features, such as grain size, phase distribution, and defects.

Remaining Life Assessment (RLA)

Remaining Life Assessment (RLA) is a crucial process used to evaluate the remaining operational lifespan of materials, components, and systems, particularly those subjected to harsh and corrosive environments.

Conventional None Destructive Testing (NDT)

Conventional non-destructive testing (NDT) methods are essential for evaluating the integrity and properties of materials and structures without causing any damage. These techniques include visual testing, PT and UT testing.